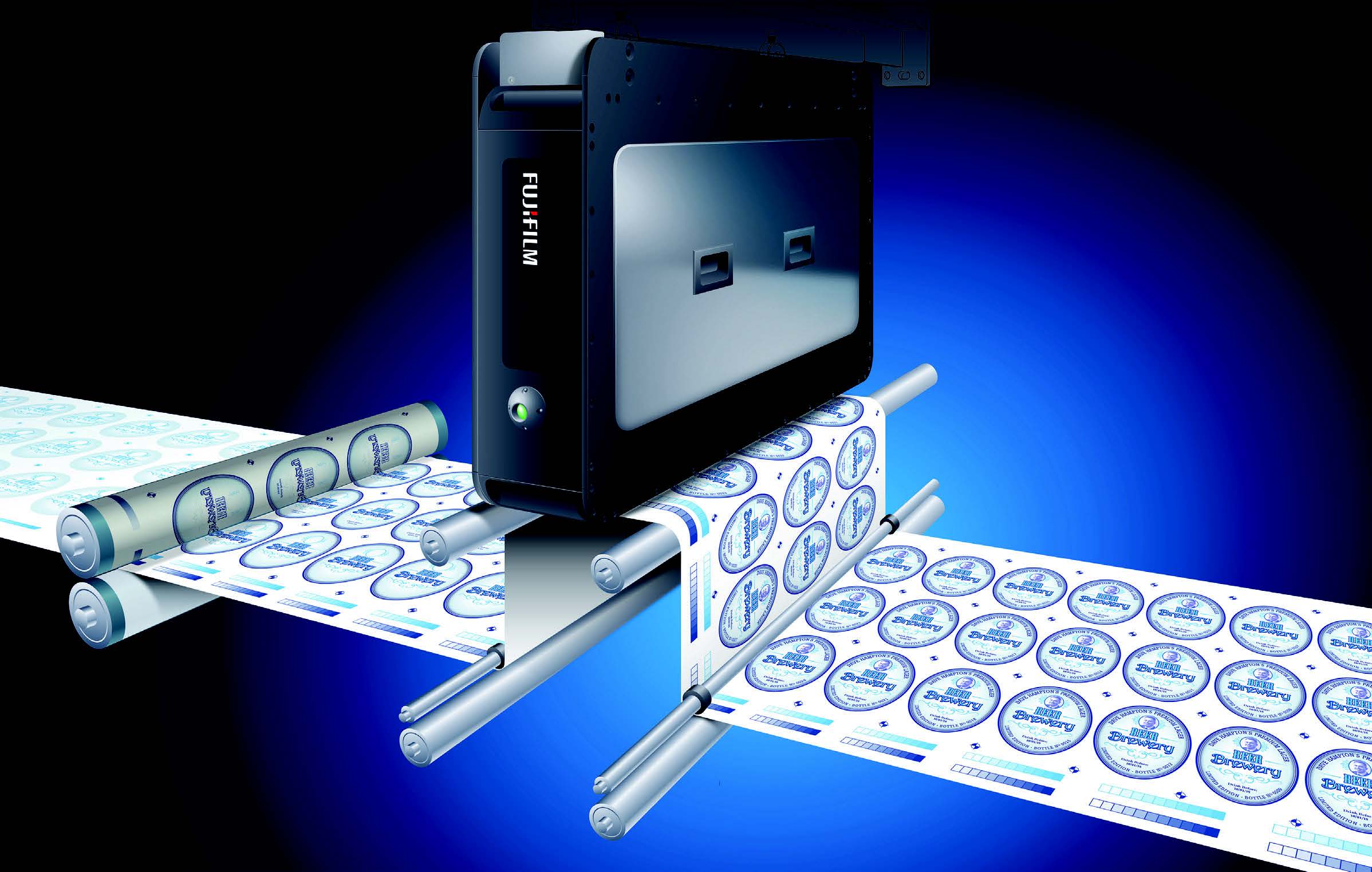

Fujifilm 42K Printbar System

by FUJIFILM Integrated Inkjet Solutions

Fujifilm's dedication to the success of its customers in production environments has resulted in an inkjet printing system with high uptime, productivity, and quality. The system can seamlessly integrate into your current operation and offer the benefit of digital printing to your clients.

The FUJIFILM 42K Printbar System uses the renowned FUJIFILM SAMBA® printhead in a highly configurable form. With 1,200 dpi, the FUJIFILM 42K Printbar system is designed to meet your print requirements from single page to multiple pages in any print width needed, and with print speeds over 1,000 feet per minute / 300 meters per minute. Or 1,800 feet per minute / 548 meters per minute in dual array configuration.

This advanced printing solution boasts a range of Fujifilm-developed technologies targeted to meet your needs for productivity, high uptime, and reliability with smooth production and quality output. This system can scale with the needs of your printing business in support of growing applications, including customer communications, publishing, and packaging.

Applications

- Personalized direct mail

- Form-based transaction imprinting

- Book and publication printing

- Corrugated cartons

- Folding cartons

- A broad range of coding and marking

FUJIFILM 42K Printbar System Features

Flexibility

The FUJIFILM 42K Printbar System is designed with print producers in mind to enable maximum benefit from your existing investments in analog presses, feeding equipment, and finishing equipment. Since the 42K System can be integrated in line with your system, you can maximize your productivity and return on investment while supporting existing, legacy or proprietary workflows.

Profitability

Fujifilm's add-on imprinting solutions are key ingredients for digitizing your conventional equipment with high quality inkjet printing. Adding digital inkjet to conventional equipment reduces typical process steps and allows continued use of existing analog printing assets.

High Uptime

The FUJIFILM 42K Printbar System leverages Fujifilm's patented REDIJET® ink recirculation system. This system ensures that ink is constantly recirculating in a closed loop that will not disrupt printing within the system. As a result, the system provides fast startup time and simplified printhead cleaning procedures.

Reliability and Quality

The silicon MEMS design of our FUJIFILM SAMBA printhead is rated for trillions of actuations for profitable operation. Coupled with the REDIJET® patented ink recirculation system, this ensures uninterrupted production with limited need for printhead refurbishment.

Technical Specifications

| Parameter | Specification |

|---|---|

| Print Width | Scalable to meet application needs in 1.6" increments |

| Print Speed & Resolution |

425 FPM / 129.5 MPM @ 1,200 dpi 615 FPM / 187.5 MPM @ 1,200 dpi 1,000 FPM / 300 MPM @ 1,200 dpi 1,800 FPM / 548 MPM @ 1,200 dpi in dual array configuration |

| Fluid | Aqueous dye inks |

| Color & Quality |

C,M,Y,K (C,M,Y,K, to monochrome conversion) 2-Bit grayscale Native drop size 2.4 or 3.5 pL Max drop size 13pL Smallest font 2 pt (4 pt knockout) |

| Print Controller |

RIP-Stream; simultaneous RIP and print RIP-to-TIFFs; jobs are ripped in advance and saved as ready to print TIFFs Output synchronization for simplex or duplex printing Print queue management using Job Tickets and Hot Folders |

| File Format & Page Data |

PDF (including ISO 32000-1 and 32000-2 PDF 2.0), PDF/VT TIFF; can be generated with the included RIP software or off-line For legacy transaction data streams, a third party conversion utility may be required |

| Print Verification | Verifies up to the first ten pages before printing for items such as: separations, cut marks, barcodes, dimensions, and density |

| Interfaces |

Manual or automatic nozzle maintenance Bulk Ink container with level sensing Monochrome |

| Power |

208-240VAC, 1Phase, 50/60Hz, 20A Max for single printbar control 208-240VAC, 3Phase, 50/60Hz, 40A Max for multiple printbar control 110-240VAC, 1Ph, 50/60Hz, 30A Max for Ink Cabinet |

Additional Options

In addition, various options are available for purchase with the 42K System to provide further flexibility:

- Dryers

- Transports

- Splice avoidance

- Automatic real time insetting

- Mounting and integration

- Extended service and support

- Rotating head assemblies (align to arched webs)

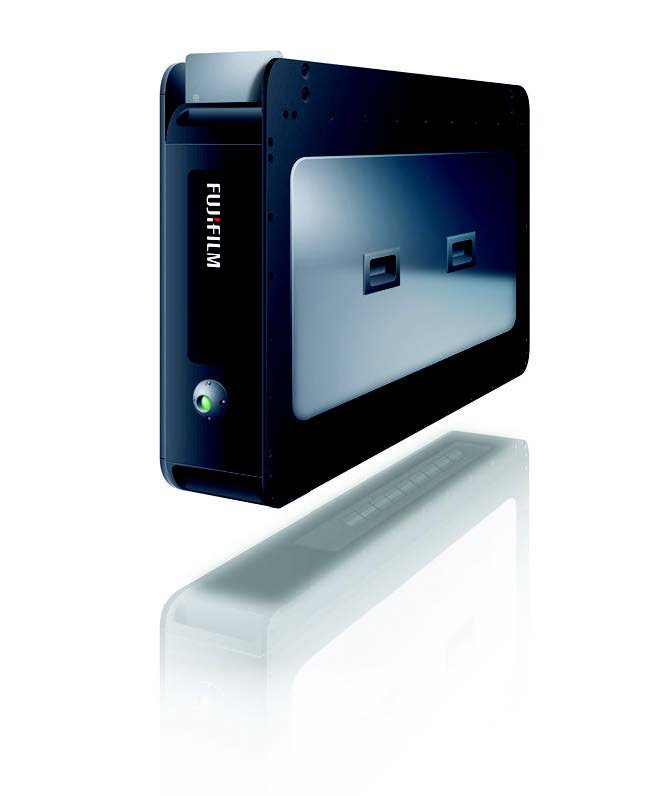

Product Images

Fujifilm 42K Printbar System - Front View

Fujifilm 42K Printbar System - Side View

Interested in the Fujifilm 42K Printbar System?

Contact us for technical specifications, integration support, and system solutions.