Piezo Inkjet Printing Technology

Advanced industrial inkjet printing systems with precise, reliable, and efficient inkjet droplet generation

Core Technology Overview

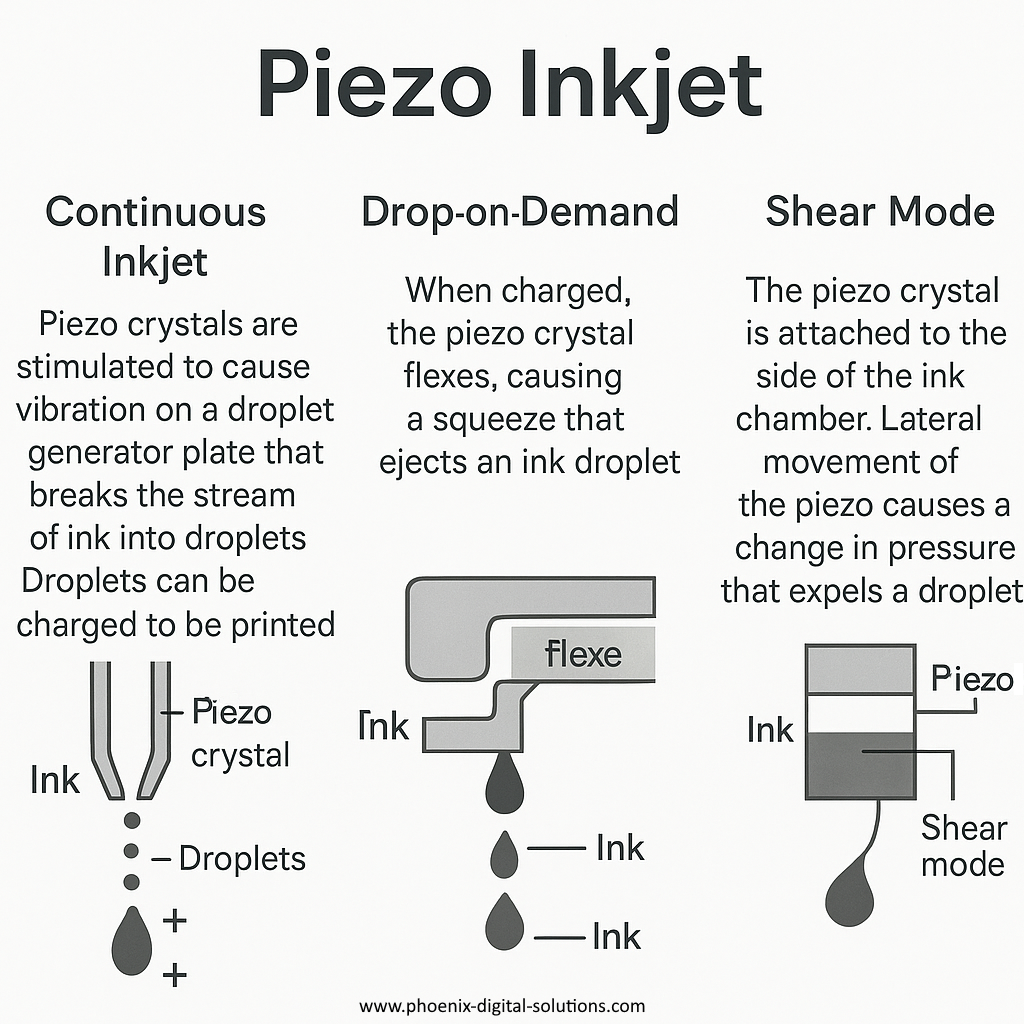

At the core of advanced industrial inkjet printing systems, piezo technology provides precise, reliable, and efficient inkjet droplet generation. We offer solutions based on two major piezo inkjet technologies—Continuous Inkjet (CIJ) and Drop-on-Demand (DOD)—as well as specialized shear mode configurations.

Continuous Inkjet (CIJ)

Continuous Inkjet printing using piezo technology involves stimulating a droplet generator plate with piezoelectric vibrations. This breaks a continuous stream of ink into individual ink droplets, which can then be charged and directed by electrostatic fields to form the printed image.

This high-speed method is ideal for variable data printing, product marking, and high-volume industrial applications, where precision and speed are critical.

Key Applications:

- Variable data printing

- Product marking

- High-volume industrial applications

Drop-on-Demand (DOD)

In Drop-on-Demand piezo inkjet printing, the piezoelectric element changes shape when electrically charged, causing a controlled pressure pulse. This pulse ejects an individual ink droplet from the nozzle only when needed, reducing ink waste and allowing for high-resolution printing with excellent edge definition.

DOD technology is widely used in graphic arts, label printing, textile printing, and packaging applications.

Key Applications:

- Graphic arts

- Label printing

- Textile printing

- Packaging applications

Shear Mode Technology

Some advanced systems use shear-mode piezo actuation, where the piezo crystal is positioned on the side walls of the ink chamber. When charged, the crystal moves laterally, creating a shear pressure wave that forces an ink droplet out.

This enables fine control over droplet volume and placement, supporting precision applications in electronics printing, bio-printing, and functional inkjet manufacturing.

Key Applications:

- Electronics printing

- Bio-printing

- Functional inkjet manufacturing

Technical Advantages

Performance Benefits

-

Precise Droplet Control

Accurate droplet size and placement for high-quality output

-

High Resolution

Excellent edge definition and fine detail reproduction

-

Wide Ink Compatibility

Works with various ink formulations and viscosities

Operational Benefits

-

Reduced Ink Waste

DOD technology only ejects droplets when needed

-

Long Service Life

Durable piezo elements with minimal wear

-

High Speed Operation

Fast printing speeds for production environments

Search Engine Optimization Keywords

Continuous Inkjet

Drop-on-Demand

Shear Mode

Why Choose Our Piezo Solutions?

Expert Knowledge

Decades of piezo inkjet technology expertise

Custom Integration

Tailored solutions for your specific requirements

Quality Assurance

Rigorous testing and validation processes

24/7 Support

Round-the-clock technical assistance

Ready to Implement Piezo Technology?

Contact us today to discuss your piezo inkjet requirements and explore the best solution for your application