Thermal Inkjet (TIJ) Printing Technology

High-speed, high-resolution inkjet printing for industrial coding, marking, and packaging applications

Core Technology Overview

Thermal Inkjet (TIJ) technology is a widely adopted method for high-speed, high-resolution inkjet printing, especially suited for industrial coding and marking, product packaging, and labeling applications. Known for its simplicity and reliability, TIJ printing uses controlled thermal energy to eject ink droplets with exceptional precision.

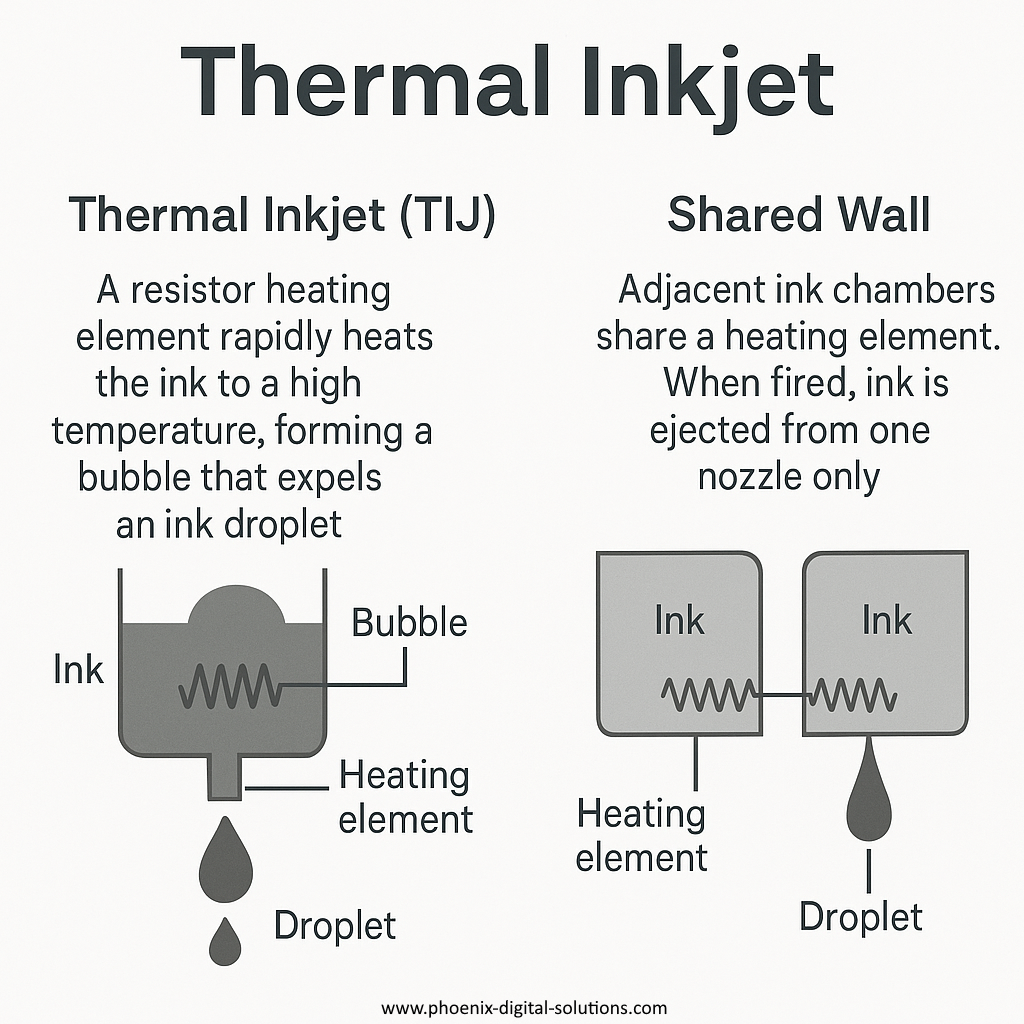

How Thermal Inkjet Works

In a standard TIJ inkjet printer, a microscopic resistor heating element rapidly heats the ink to over 300°C in just a few microseconds. This sudden heat causes the ink to vaporize, forming a tiny bubble. As the bubble expands, it forces an ink droplet through the nozzle and onto the substrate. Once the bubble collapses, the chamber refills and the cycle repeats—enabling printing speeds of up to thousands of drops per second.

TIJ technology delivers sharp, clean text and barcodes on porous and non-porous surfaces without moving parts, making it ideal for low-maintenance inkjet coding systems.

Key Features:

- Microsecond heating to 300°C

- Bubble formation and collapse cycle

- Thousands of drops per second

- No moving parts design

Process Flow

Shared Wall Thermal Inkjet Design

Some advanced TIJ systems use a shared wall architecture, where adjacent ink chambers share a heating element. When activated, the resistor heats one chamber at a time, allowing compact nozzle arrangements and increased printhead density.

This design offers efficient energy use, smaller printhead footprints, and excellent print quality across a variety of industrial substrates.

Design Benefits:

- Compact nozzle arrangements

- Increased printhead density

- Efficient energy use

- Smaller printhead footprints

Shared Wall Architecture

Adjacent chambers share heating elements for compact, efficient design

Why Choose Thermal Inkjet for Industrial Applications?

Key Advantages

-

Low Maintenance

No moving parts or wear-prone mechanisms

-

High Reliability

Consistent performance in harsh production environments

-

Excellent Resolution

Crisp, legible codes and graphics

Additional Benefits

-

Fast Drying Inks

Ideal for porous materials and coated substrates

-

Plug-and-Play Integration

Easily installed into production lines, packaging systems, and mailing equipment

-

High-Speed Operation

Thousands of drops per second for production efficiency

Industry Applications

TIJ printers are widely used in the food and beverage, pharmaceutical, cosmetics, and logistics sectors, where reliable, fast, and accurate printing is essential.

Food & Beverage

Product coding and expiration dates

Pharmaceutical

Medicine packaging and labeling

Cosmetics

Product marking and batch codes

Logistics

Shipping labels and tracking codes

Search Engine Optimization Keywords

Standard TIJ Technology

Advanced TIJ Design

Why Choose Our Thermal Inkjet Solutions?

Low Maintenance

No moving parts for reliable operation

High Reliability

Consistent performance in harsh environments

Excellent Resolution

Crisp, legible codes and graphics

High Speed

Thousands of drops per second

Ready to Implement Thermal Inkjet Technology?

Contact us today to discuss your thermal inkjet requirements and explore the best solution for your industrial application