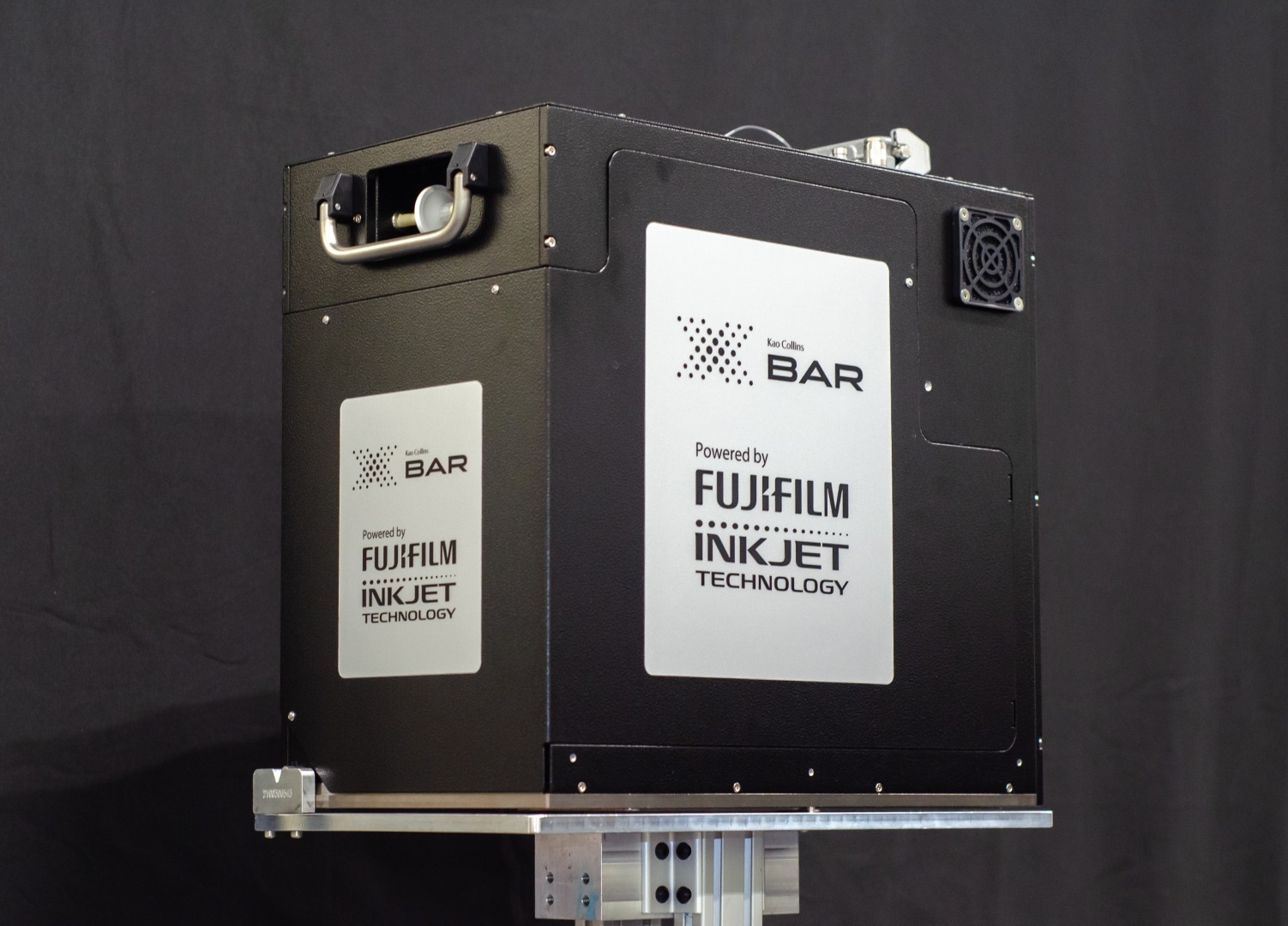

XBAR Printhead Technology

Revolutionary digital inkjet technology for industrial applications

The XBAR printhead represents the pinnacle of digital inkjet technology, offering exceptional print quality and reliability. Available in both 4-inch and 9-inch widths, it delivers precise droplet control and consistent performance across various substrates.

Powered by Fujifilm's cutting-edge Samba printhead technology and integrated with Fuji Dimatix fluid systems, the XBAR provides seamless compatibility with the Universal Controller for complete system integration.

Direct Kodak Versamark Replacement: The XBAR system with Universal Controller is a direct replacement for Kodak Versamark systems including the 4" 6240, 9" DT90, and DH9000. We also offer replacement solutions for 1" and 2" Kodak systems - contact us to find out more about your specific requirements.

Key Features

- 1200 x 600 DPI resolution for exceptional print quality

- Fujifilm Samba G3L printhead technology

- Universal Controller compatibility

- Fuji Dimatix fluid system integration

- Variable drop size technology (6 picoliters)

Interested in XBAR Technology?

Contact us for technical specifications, integration support, and system solutions.

Get Quote KaoCollins Innovation DayTechnical Specifications

Performance

- Print Resolution

- 1200 x 600 DPI

- Print Speed

- Up to 1750 f/min

- Droplet Size

- 6 picoliters (variable)

- Print Distance

- 2mm from substrate

Printhead Configurations

- 4" Module

- 2 arrays × 3 Samba G3L

- 9" Module

- 1 array × 6 Samba G3L

- Nozzle Count

- 11,264 nozzles per array

- Printhead Lifetime

- 10,000-20,000 hours

Technology Integration

KaoCollins Universal Controller

Seamless integration with KaoCollins Universal Controller for precise waveform control and system optimization

Fujifilm Samba

Advanced Samba G3L printhead technology delivering exceptional print quality and reliability

Fuji Dimatix

Professional fluid systems providing precise ink delivery and management for optimal performance

Applications

Direct Mail

High-volume personalized printing for direct mail campaigns with variable data capabilities

Transactional Documents

High-speed printing for bills, statements, and transactional documents with superior quality

Labels & Packaging

Variable data printing for labels and packaging applications with precise barcode generation

System Benefits

Operational Efficiency

- • 1-5 minute restart times

- • Idle mode capability (no full shutdown)

- • No charge shorts or lengthy shutdowns

- • Up to 50% ink consumption reduction

Print Quality

- • 1200 x 600 DPI resolution

- • Variable drop size technology

- • Precise droplet placement

- • Consistent print quality

XBAR Printhead Key Benefits

Revolutionary advantages that transform your printing operations

Maximum Uptime

No charge shorts, no streakers, continuous operation without interruptions

Cost Savings

40-50% less ink consumption, no pay per hourly charges for refurbishments

Reduced Downtime

Minimal maintenance requirements, faster restart times, less waste

Compact Design

Smaller footprint, lower power consumption, space-efficient solution

Customer Success Story

American Litho - XBAR System Success

Location: Carol Stream, IL, USA

Challenge: Replace existing Kodak Versamark Printing system

Solution: KaoCollins XBAR printhead system with Universal Controller

Related Items

X-BAR System Overview

The X-BAR system revolutionizes traditional printing by introducing digital, variable printing capabilities, including barcodes, text elements, logos, and more. It employs drop-on-demand inkjet technology that is both reliable and cost-effective, while delivering outstanding image quality, even in font sizes as small as 2 points and 1D barcodes as tiny as 6.7 mils.

X-BAR seamlessly integrates with legacy systems and is supported by Fujifilm's cutting-edge Samba Printhead technology, KaoCollins' superior ink products, and Phoenix Digital Solutions' expertise, ensuring a smooth transition to modern inkjet technology for applications such as direct mail, transactional printing, promotional materials, and beyond.

💧 Ink and Substrate Compatibility

Compatible Inks

- • Water-based dye inks

- • Water-based pigment inks

- • Pigment polymer inks

- • UV-curable inks

- • Electron beam (EB) curable inks

Ink Consumption: Up to 50% reduction compared to legacy systems

Substrate Compatibility

- • Porous bond papers

- • High-gloss coated stock

- • Films and foils

- • Various industrial substrates

Note: Matched with the right ink for optimal results

X-BAR Applications

Direct Mail

Variable data printing for personalized mail campaigns

Transactional Printing

High-speed variable data for bills and statements

Promotional Materials

Custom logos, barcodes, and variable content

X-BAR Benefits

Operational Efficiency

- • Idle mode capability (no full shutdown)

- • No charge shorts or lengthy shutdowns

- • Up to 50% ink consumption reduction

Print Quality

- • 1200 x 600 DPI resolution

- • Variable drop size technology

- • Precise droplet placement

- • Consistent print quality

Technology Overview

SAMBA Printhead Technology

SAMBA is an extensible "printhead on a chip" technology analogous to the evolution of Integrated Circuits (IC) to Large Scale Integration (LSI). This breakthrough in industrial inkjet printhead design combines the packing density and cost of Thermal Ink Jet (TIJ) with the high throughput of Continuous Ink Jet (CIJ) while providing the operational flexibility of Piezo Ink Jet (PIJ).

SAMBA is developed by: Fujifilm

MEMS Technology

Silicon Micro-Electro-Mechanical Systems (MEMS) are used in piezo printhead 'channel' plates, the channels from the ink manifold to the actuator chamber, and then to the nozzles. These ultra-small components make high-speed, high-resolution industrial inkjet printing possible.

Resolution Options: 300, 600, or 1,200 DPI process resolution